Calaamadda birta, biinanka birta, birta khaaska ah, clips, calaamada dugsiga

Socodka shaqada

| Magaca Alaabta | Calaamadda Birta/Biinanka birta |

| Qalab | Zinc daawaha |

| Qiimaha tixraaca | 0.5 ilaa 3 USD |

| Samee dalabaad yar | 500PCS |

| Taariikhda keenista | 5 maalmood dhalista |

| OEM | OK |

| Goobta wax soo saarka | lagu sameeyay Shiinaha |

| Mid kale | Oo ay ku jirto baakad |

Waxaa jira noocyo badan oo calaamado bir ah, oo ay ku jiraan calaamado, koofiyado, calaamado koofiyad, calaamado garbaha, calaacalaha, billadaha, biladaha, calaamadaha xusuusta, calaamadaha, iwm.

Calaamadaha dahabiga ah waxaa lagu farsameeyaa dhaldhalaalka, dhaldhalaalka ku dayashada, dubista, xaradhka, daabacaadda, calaamadaynta shaabadda.Habka ugu caansan waa dubista, dhaldhalaalka ku dayashada, shaabadeynta, iyo habab kale: xardho (etching), daabacaadda shaashadda, daabacaadda offset, iyo saamaynta 3D.

1,Calaamadaha dhaldhalaalka jilicsan ( dhaldhalaalka ku dayashada ah): calaamadahani waa kuwo aad u wanaagsan xagga shaqada, midabkooduna qurux badan yahay, mid aad u wanaagsan xagga shaqada oo siman;Dusha sare waa mid siman, xariiqyada dusha sare waxay noqon karaan kuwo dahab ah, qalin ah iyo midabyo kale oo bir ah, oo leh midabyo kala duwan oo ka buuxsamay inta u dhaxaysa xariiqyada birta;Waxay ku siinaysaa dareen aad u sarreeya oo raaxo leh Waa doorashada koowaad ee habka samaynta calaamad.

2. Ku shubista: marka la barbar dhigo calaamado kale, dusha sare ee calaamaduhu waa saddex-cabbir, calamadahan ayaa inta badan lagu daraa dhaldhalaalka jilicsan ama farsamada dubista.

3. Shaabadaynta+ rinjiga dubista+ dhibicda xabagta: calaamad noocan oo kale ah waxay leedahay substrate qaro weyn dhinaca, dhibicda xabagta hufan ee dusha sare, midab dhalaalaya, xariiqyo cad oo dhalaalaya, iyo muuqaal xoog leh;Dusha calaamada birta shaabadaysan waxay qaadan kartaa koronto-samayn kala duwan

daaweynta.

4. Shaabadeynta+lithography+ koollada: substrate-ka calaamada noocaan ah aad buu u dhuuban yahay dhinaca, lakabka xabagta xabagta ayaa xoogaa dhumuc ah leh;Guud ahaan, garaafyada waa kuwo fudud.Daabacaadda shaashadda waa la isticmaali karaa iyada oo aan si tartiib tartiib ah midabka isbeddelin.Daabacaadda shaashadu way fududahay in la shaqeeyo.Haddii garaafyada ay fudud yihiin, waxaa lagu isticmaali karaa qiimo ka hooseeya daabacaadda.Si kastaba ha ahaatee, haddii garaafyada ay si tartiib tartiib ah u beddelaan midabka, waxaa kaliya oo lagu daabici karaa daabacaadda offset.Guud ahaan, ka dib marka la qalajiyo, lakabka resin hufan (Poly) ayaa lagu dari doonaa dusha sare ee qaabka si loo ilaaliyo qaabka.

5, Stamping+electroplating: Noocan calaamada waxa lagu gartaa oogada macdan.Waxaa mararka qaarkood loo isticmaalaa iyadoo lagu darayo dhaldhalaalka jilicsan ama habka dubista.Guud ahaan, waxay ka samaysan tahay naxaas jilicsan (birtu way ka jaban tahay, laakiin uma qurux badna sida naxaasta), kaas oo lagu riixo mashiinnada hydraulic hal mar.Tooshka gacanta ka dib, xadhkaha calaamaduhu waa cad yihiin oo qurux badan.

6. Daxalka + dubitaanka varnish: Alaabooyinka saxan qaniinyada waxay leeyihiin sifooyinka khadadka wanaagsan iyo midabka guud ee quruxda badan, oo lagu daray lakabka resin ilaalinta (Poly) oo lagu daray dusha sare ee calaamadda.

7、 Calaamadda daasadda: Tinplate waa xaashi bir ah oo dusha sare ku leh lakabka tiin, kaas oo aan si fudud loo miridhkumin, sidoo kale loo yaqaanno tinplate;Qaabka dusha sare waa la daabacay.

Calaamad, waa maxay calaamad, calaamad, hordhac calaamad, taariikhda calaamad

Astaantu waa wakiilka ama calaamada nooc ka mid ah shay xilli.Waa in ay ka kooban tahay macne taariikheed qani ah oo ka dambeeya.Astaanta lafteedu sidoo kale waa farsamada gacanta, sidaas darteed waxaa jecel dad badan oo badan.Hadda waxa ay noqotay urur dadweyne, calaamaduhuna waxa ay ka mid yihiin waxyaabaha aan laga maarmi karin ee suuqyada qadiimiga ah iyo kuwa qashinka ah;

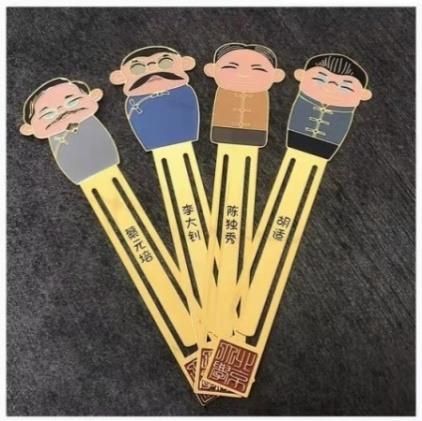

Marka loo eego hawlo kala duwan, calamadaha waxaa inta badan loo qaybin karaa calaamado, sida calaamada dugsiga, calaamada shirkadda, iyo astaanta shirkadda.Bilad, astaan sharaf ay dawladu ama unug siiso qof adeeg mudnaan leh.Calaamadaha xusuusta ayaa ah kuwa ugu badan ee la soo saaro, sida calaamadda xusuusta ee Guddoomiye Mao, calaamadaha munaasabadaha waaweyn ee kala duwan, calaamadaha xuska ee xafladaha kala duwan.Calaamadaha farsamada gacanta, calaamadaha dahabka, calaamado loo soo saaray qurxinta kaliya.

Calaamadaha waxaa loo qaybin karaa calaamado xardhan, calaamado koronto ku xiran, calaamado gudaha ah, calaamado la tuuray, iwm. iyadoo loo eegayo habka wax soo saarka.

Marka loo eego da'da, calaamadaha waxaa loo qaybin karaa calaamado hore ka hor sannadihii hore ee Jamhuuriyadda Shiinaha, calaamado dhexe ka hor iyo ka dib xoriyada, calaamado kacaan dhaqameed iyo calaamado casri ah.

Calaamadaha waxaa loo qaybin karaa calaamado bir ah, calaamado dhoobo ah, calaamado alwaax ah, calaamado caag ah, calaamado bakelite, iwm;Calaamadaha birta ayaa ah kuwa ugu badan, bacaha caaga ah maaha kuwo xidhashada u adkaysta, xidhiddooda iyo ururintooduna waa xadidan tahay.Astaamaha ka samaysan birta birta ah ee la sameeyay sanadihii ugu dambeeyay waa kuwo khafiif ah, quruxsan, midabkoodu saxan yahay, oogada dhalaalaysa oo adkaysi u leh daxalka Biladyada Copper guud ahaan waa bilado xusuus gaar ah, kuwaas oo lagu garto dhalaal, qallafsan iyo qaali, gaar ahaan naxaasta cas, oo leh qaabka boqorka.Calaamadaha dahabiga ah ayaa ah kuwa ugu fiican calaamadaha.Guud ahaan waxaa lagu soo saaraa tiro xadidan oo loogu talagalay hawlo xuseed gaar ah Dusha sare ee shaabada dhoobada waa siman oo dhalaalaya, daxalka u adkaysta laakiin jilicsan.Xirmooyinka dhoobada waa naadir oo guud ahaan waxay leeyihiin farshaxan sare iyo qiimo ururin Bamboo waxay ka sarreeyaan tignoolajiyada wax soo saarka, texture, midabka, iwm. Way fududahay in la dillaaco waqooyiga qalalan.

Siyaabaha lagu helo calaamaduhu waa qaybinta, qaadashada, xaadirka, dhaxalka, beddelka, gadashada iyo calaamado kale oo casri ah, qaar ka mid ah calaamadaha inta badan loo isticmaalo qurxinta ayaa sidoo kale loo yaqaannaa brooches, baaj, biinanka lapel, biinanka lapel iyo biinanka.

Sharaxaadda halyeyga ee habka wax-soo-saarka calaamadda, hordhaca dhaldhalaalka, dhaldhalaalka ku dayashada, varnish dubitaanka, saxan qaniinyada, daabacaadda, habka wax-soo-saarka calaamadda shaambada:

Habka ugu caansan waa dubista varnish, dhaldhalaalka ku dayashada, shaabadeynta, iyo hababka kale: qaniinyada (etching), daabacaadda shaashadda, daabacaadda offset, saamaynta stereoscopic 3D, iwm.

Rinjiga sawirka weyn.Qaybta concave waxaa lagu rinjiyeeyaa midabyo kala duwan, halka qaybta convex-ka lagu rinjiyeeyo midabyo kala duwan oo bir ah sida dahab iyo nikkel.

Astaamaha rinjiga dubista: midab dhalaalaya, xariiqyo cad iyo muuqaal xoog leh.Copper ama birta waxaa loo isticmaali karaa sidii alaab cayriin ah, iyo calaamadaynta rinjiga birta lagu dubayo waa ka raqiisan yihiin kana fiican yihiin.Haddii miisaaniyaddaadu yar tahay, tani waa tan ugu habboon!

Dusha sare ee calaamadda dhaldhalaalka ee la dubay waxa lagu dahaadhay lakabka resin ilaalinta hufan (Polly), kaas oo inta badan loo yaqaanno "xabag daadanaya" (xusuusnow in midabka calaamaddu uu yara fududaan doono ka dib marka xabagta ay tifqdo dib u laabashada awgeed. iftiinka)

Dusha sare ee calaamadda dhaldhalaalka ku dayashada ayaa siman.Xadadka dusha sare waxaa lagu dhejin karaa dahab, qalin iyo midabyo kale oo bir ah, midabyo kala duwan ayaa ka buuxa inta u dhaxaysa xariiqyada birta ah.

Habka wax soo saarka ee calaamadda dhaldhalaalka ku dayashada ayaa la mid ah kan calaamadda dhaldhalaalka (calaamada cloisonne).Farqiga u dhexeeya dhaldhalaalka ku dayashada iyo dhaldhalaalka dhabta ah ayaa ah in midabada dhaldhalaalka la isticmaalo ay kala duwan yihiin (mid waa midabka dhaldhalaalka dhabta ah, kan kalena waa midabka dhaldhalaalka synthetic)

Calaamadaha dhaldhalaalka oo kale ah waxay leeyihiin shaqo aad u wanaagsan, oog siman, oo si gaar ah u jilicsan, oo siinaya dareen aad u sarreeya oo raaxo leh Waa doorashada koowaad ee habka samaynta calaamadda Haddii aad rabto inaad marka hore samayso calaamad qurux badan oo heer sare ah, fadlan dooro ku dayashada calaamad dhaldhalaalka

Calaamadaha shaabadeynta: Calaamadaha shaabadeynta guud ahaan waxay ka samaysan yihiin naxaas (naxaas cas, naxaas cas, iwm.), zinc alloy iyo birta Sababtoo ah naxaasku waa kan ugu jilicsan, khadka calaamadda naxaasta ah ayaa ugu cad, oo ay ku xigto zinc alloy, iyo qiimaha calaamad u dhiganta naxaasta xardhan ayaa sidoo kale ah kan ugu sarreeya

Calaamadaha shaambada leh waxaa lagu dhejin karaa saameyno kala duwan, oo ay ku jiraan dahab, nikkel, naxaas, naxaas iyo dahaadh qalin ah Qaybta cajaa'ibka ah ee calaamadda shaabadda ayaa sidoo kale loo habayn karaa saameyn carro leh.

Calaamadaha Daabacaadda: waxay u qaybsan yihiin daabacaadda shaashadda iyo daabacaadda fidsan Waxa kale oo loo yaqaan calaamadda tuurista xabagta sababtoo ah habka ugu dambeeya ee calaamaddu waa in lagu daro lakabka ilaalinta hufnaanta (Boli) ee dusha sare ee calaamadda.Alaabooyinka la isticmaalo waxay u badan yihiin birta iyo naxaasta, naxaasta ama naxaasta oogada ay calaamaddu ku daabacan tahay maaha mid koronto ah, laakiin waa midab dabiici ah ama la cadayday.

Calaamadaha daabacan ee shaashadda waxaa inta badan loogu talagalay garaafyada fudud, midabada yar, iyo taarikada daabacaadda shaashadda ee ka jaban

Daabacaadda saxanka: ee qaababka adag iyo midabyo badan, gaar ahaan midabada gradient,

Saamaynta concave convex ee dusha calaamada: rinjiga dubista, shaabadaynta (oogada waxa lagu dahaadhay karaa dahab, nikkel, iwm.)

Dusha sare ee calaamaddu waa fidsan tahay: shaashad daabacan, cloisonne (dhalaal), ku dayasho cloisonne ( dhaldhalaalka), saxan qaniinyo, iyo calaamad nooca qudhuntay.

Midabka qaabku wuxuu leeyahay isbeddel tartiib tartiib ah: daabacaadda offset waa in la isticmaalaa (sidoo kale loo yaqaan lithography, haddii nambarku yar yahay, daabacaadda offset-ka iyo kharashka samaynta saxanka ayaa noqon doona mid sarreeya).Guud ahaan, lakabka resin ilaalinta hufan (sidoo kale loo yaqaan Boli, oogada wax yar ayaa kor loo qaadi doonaa) ayaa lagu dari doonaa dusha sare

Xulashada qalabka calaamadaha: naxaas (la taliyay), birta aan fiicnayn, birta (qiimaha hooseeya, laakiin si sahlan u miridhku, iwm, laguma talinayo), walxaha kale ee aan birta ahayn (acrylic, galaas organic, saxan laba midab leh, PVC koollo jilicsan, iwm, sida acrylic, saxan laba midab ah iyo qalab kale oo aan biyuhu u adkaysan karin waa in loo isticmaalo samaynta taarikada furaha musqusha iyo meelaha kale ee biyaha leh);

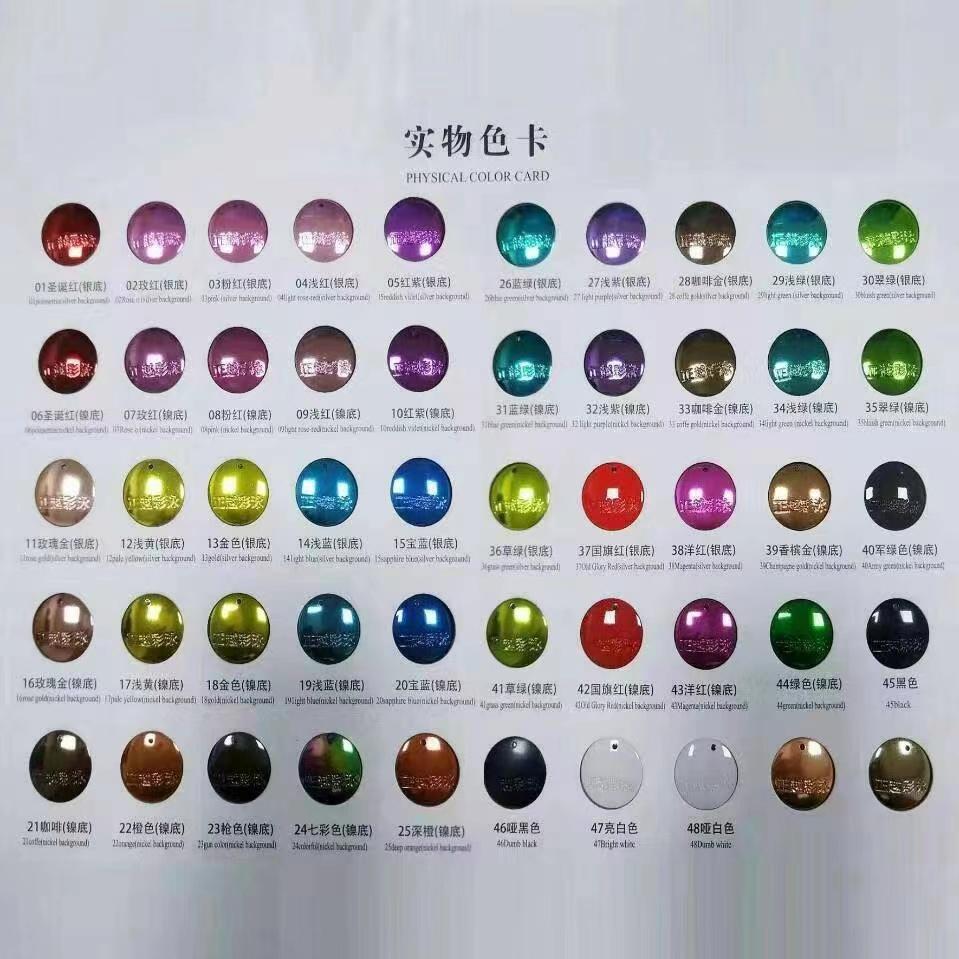

Xulashada saamaynta daaweynta dusha sare ee korantada ee dusha calaamadda: sida ku cad sawirro kala duwan, waxaa lagu dhejin karaa dahab, nikkel (caddaan cad), naxaas, iwm. Dusha sare waxay noqon kartaa ciid, matte, iwm. (oo sidoo kale loo yaqaan Poly) ayaa lagu dari karaa;

Xulashada qiimaha calaamadda: Qiimaha waxaa inta badan go'aamiya agabka, hababka iyo tirada.Haddii miisaaniyadu ku filan tahay, fadlan dooro calaamad naxaas ah.Haddii qiimuhu jaban yahay, fadlan dooro calaamad bir ah

Qiimaha guud waa dhaldhalaalka>anti dhaldhalaalka>dubidda varnish, shaabad>qaniinyada nooca, nooca xun, daabacaadda;

Talo soo jeedinta garaafyada naqshadaynta calaamada: Marka ay sawiradu aad u adag yihiin iyo midabada badan, ayaa qiimihiisu kor u sii kacayaa.Waxaa intaa dheer, saameyno badan laguma gaari karo wax soo saarka calaamadda dhabta ah.Tusaale ahaan, haddii fogaanta tooska ah ee khadadka ay ka yar tahay 1mm, way adkaan doontaa in la xakameeyo Dhammaan sawirada waa inay ahaadaan kuwo fudud oo deeqsi ah intii suurtagal ah Waxaan u baahanahay inaan si joogto ah ula xiriirno naqshadeeyayaashayada kahor iyo inta lagu jiro dhammaan habka naqshadeynta sawirada calaamadda vector Software garaafyada aan isticmaalno waa CorelDraw iyo Illustrator.

Habka wax soo saarka

| Qalab | Zinc alloy, iwm. | MOQ | 300PCS |

| Naqshadeynta | Habbee | Waqtiga tusaalaha | 10 maalmood |

| Midabka | Daabacaadda | Waqtiga wax soo saarka | 30 maalmood |

| Cabbirka | Habbee | Baakad | Habbee |

| calaamad | Habbee | Shuruudaha lacag-bixinta | T/T (wareejinta isgaarsiinta) |

| Asal ahaan | Shiinaha | Debaajiga dhimista | 50% |

| Faa'iidadayada: | Sannado khibrad xirfadeed;adeega isku dhafan ee naqshadaynta ilaa wax soo saarka;jawaab celin degdeg ah;maaraynta alaabta wanaagsan;wax soo saar degdeg ah iyo caddayn. | ||

Qaybaha alaabta

-

Taleefanka

-

E-mailka

-

WeChat

Judy

-

Skype

Skype

-

Sare

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur